Model Description | Unit | Specifications | |||||||

|

| MW1320 | M1332 | M1350 | M1363 | M1380 | |||

General capacity | |||||||||

Distance between centers | mm | 500、750 500、750 | 1000、1500、2000、3000 | 1500、2000、3000 | 3000、4000、5000 | 3000、4000、5000 | |||

Center height | mm | 135 | 180 | 270 | 335 | 500 | |||

Dia. Ground(O.D) | mm | 5~200 | 8~320 | 25~500 | 30~630 | 50~800 | |||

Max. length ground(O.D) | mm | 500、750 500、750 | 1000、1500、2000、3000 | 1500、2000、3000 | 3000、4000、5000 | 3000、4000、5000 | |||

Max. weight of work piece | Kg | 100 | 150 | 1000 | 3000 | 5000 | |||

Workhead | |||||||||

Center taper(MT) | (MT) | 4 | 5 | 6 | metric 80# | Metric 100# | |||

Spindle speed | r/min | 50HZ:25~380 Stepless | 26、52、90、130、180、260 | 50HZ:18~140 | 50HZ:10~100 | 50HZ:6~60 | |||

Wheelhead | |||||||||

Wheel spindle speed | r/min | 1335 | 1100 | 870 | 740 | 740 | |||

Wheelhead rapid travel | mm | 50 50 | 50 50 | 100 | 100 | 100 | |||

Max. travel | mm | 205 | 235 | 438 | 475 | 550 | |||

Hand feed per. rev | | rough: 2 fine:0.5 | rough: 2 fine:0.5 | rough:4 fine:0.5 | rough:6 fine:0.5 | rough:6 fine:0.5 | |||

Hand feed per gra. | | rough:0.01 fine:0.0025 | rough:0.01 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | rough:0.02 fine:0.0025 | |||

Max. dimension of wheel(OD×W×ID) | mm | 500×50×203 | 600×63×305 | 750×75×305 | 750×75×305 | 900×75×305 | |||

Wheel peripheral velocity | m/s | 35 35 | 35 35 | 35 | 35 | 35 | |||

Table | |||||||||

Hand feed per. rev | mm | 6 6 | 6 6 | 5 | 5 | 5 | |||

Max. swiveling angle of table | clockwise | ° | 3°(500)、8°(750) | 3°(1000、1500)、2°(2000、3000) 3° | 3°(1500)、2°(2000、3000) | 2°(3000)、1°(4000、5000) | 2°(3000)、1°(4000、5000) | ||

| anticlockwise | ° | 9°(500)、8°(750) | 7°(1000)、6°(1500)、5°(2000)、3°(3000) | 6°(1500)、5°(2000)、3°(3000) | 3°(3000)、2°(4000、5000) | 3°(3000)、2°(4000、5000) | ||

Longitudinal traverse speed of table | m/min | 0.1~4 | 0.1~4 | 0.1~3 | 0.1~4 | 0.1~4 | |||

Tailstock | |||||||||

Center tape(MT) | (MT) | 4 | 4 | 6 | Metric 80# | Metric 100# | |||

Quill travel | mm | 30 | 30 | 70 | 100 | 100 | |||

Motor | |||||||||

Wheelhead motor power | Kw | 5.5 | 11 | 15 | 7/11 | 18 | |||

Workhead motor power | Kw | 0.75 | 0.75/1.5 | 2.2/3.6 | 15 | 18 | |||

Machine | |||||||||

Gross weight | t。 | 4 (500)、4.2 (750) | 5.3 (1000)、6.1 (1500)、7.9(2000)、9.9(3000) | 11.2 (1500)、13 (2000)、17.4 (3000) | 28(3000)、34(4000)、39(5000) | 33(3000)、40(4000)、45(5000) | |||

Packing dimension | cm | 235×203×205(500) 275×203×205(750) | 338×200×205(1000) 438×200×205(1500) 540×200×205(2000) 739×200×205(3000) | 6100×2280×2100(1500) 6100×2280×2100(2000) 8100×2280×2100(3000) | 8800×2800×2200(3000) | | |||

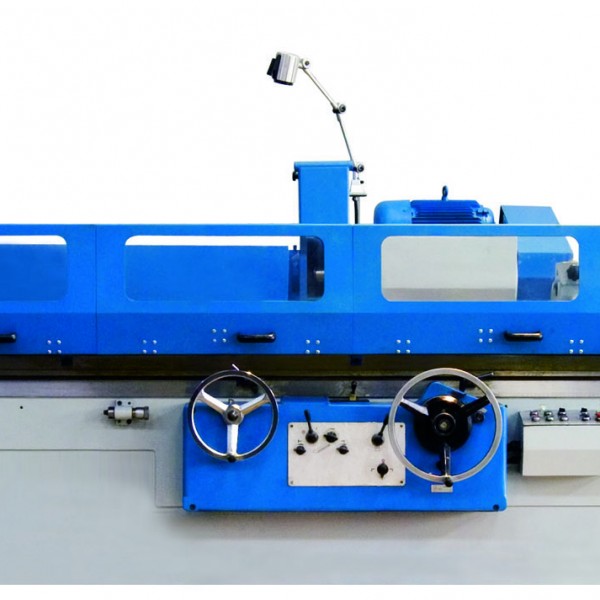

M13 series cylindrical surface grinder is suitable for grinding outer surface of cylinder and taper.

it is suitable for single and small batch production.

The longitudinal movement of the workable is driven by hydraulic or by handwheel,the worktable can rotate to a certain degree so as to be suitable for grinding taper.

The wheel head cross feed is driven by hydraulic,which realizes automatic periodical feed and rapid feed.it can also do rough and fine feed through handwheel.

The work head spindle,wheel head spindle,internal grinding spindle,coolant pump,hydrodynamic and hydrostatic oil pump are driven by separate motors

The spindle of M1350 series is supported by hydrostatic and hydrostatic lubrication,its movement on low speed is smooth.

The spindle of M1350 series is supported by hydrostatic and hydrodynamic bearing of high rigidity,it makes the spindle have high rotary accuracy and perfect rigidity.

The wheel head of M1350 adopts double – speed motor and its speed can be changed by changing the position of belt.

Each moving parts of the machine has electrical, hydraulic and mechanic interlock structure the machine is well designed with pleasing appearance,all control lever are centralized in panel make operating easy.

The wheel dresser can be assembled on the worktable surface or on the tailstock.

There have many different distance between the centers for choice.

Standard accessories:

(1) complete set of electrical equipment (2) coolant equipment (3) wheel periphery dresser (4) wheel flange (5) wheel balancing arbor (6) leveling wedge

(7) open type steady rest (8) carbide tipped center

Optional accessories:

(1) wheel balancing stand (2) magnetic separator (3) center grinding attachment

(4) close type steady rest (5) end wheel dresser (6) radius wheel dresser

,