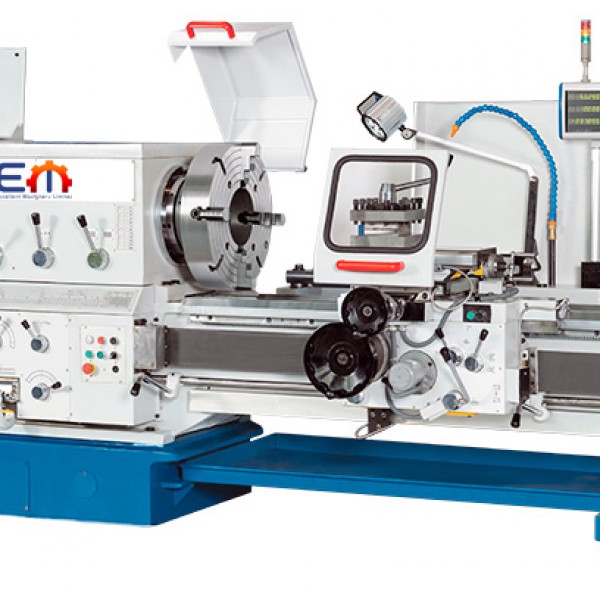

Feature:

heavy machine bed made of premium cast-iron with hardened and ground guideways

massive headstock with high-precision spindle running in tapered roller bearings, and 2 lathe chuck mounts on both sides

gears are hardened and ground

high torque at the working spindle ensures high chip removal rates when machining parts with large diameters

powerful main drive motor with 7,5 kW power

central, practical controls for feeds and thread leads

wide spectrum of inch and metric threads

heavy-duty 4-station tool holder

coolant system is included

taper turning unit with 500 mm turning length

| Box-way Lathe | TubeTurn 135 | TubeTurn 200 | TubeTurn 225 |

| working area | |||

| workpiece length (max.) | 1350 mm | 1350 mm | 1350 mm |

| turning diameter over bed (max.) | 630 mm | 630 mm | 670 mm |

| turning diameter over support (max.) | 350 mm | 350 mm | 390 mm |

| travel X-axis | 340 mm | 340 mm | 340 mm |

| travel Z-axis | 1350 mm | 1350 mm | 1350 mm |

| headstock | |||

| speed range | 14 – 750 rpm | 17 – 300 rpm | 17 – 300 rpm |

| headstock torque | 2700 Nm | 2050 Nm | 2050 Nm |

| lathe chuck diameter | 400 mm | 500 mm | 500 mm |

| spindle bore | 135 mm | 200 mm | 225 mm |

| spindle bore in chuck | 133 mm | 197 mm | 223 mm |

| feed | |||

| rapid feed X-axis | 4000 mm/min | 4000 mm/min | 4000 mm/min |

| rapid feed Z-axis | 4000 mm/min | 4000 mm/min | 4000 mm/min |

| tool head | |||

| number of tool stations | 4 Pieces | 4 Pieces | 4 Pieces |

| tool shank dimensions | 32×32 mm | 32×32 mm | 32×32 mm |

| tailstock | |||

| tailstock quill diameter | 100 mm | MT 5 | MT 5 |

| tailstock taper | MT 5 | 100 mm | 100 mm |

| tailstock quill stroke | 205 mm | 205 mm | 205 mm |

| drive capacity | |||

| motor rating main drive | 11 kW | 7,5 kW | 7,5 kW |

| total power consumption | 12 kVA | 9 kVA | 9 kVA |

| measures and weights | |||

| overall dimensions | 3657x1449x1393 mm | 3657x1449x1393 mm | 3657x1449x1413 mm |

| weight | 4100 kg | 4190 kg | 4264 kg |

,